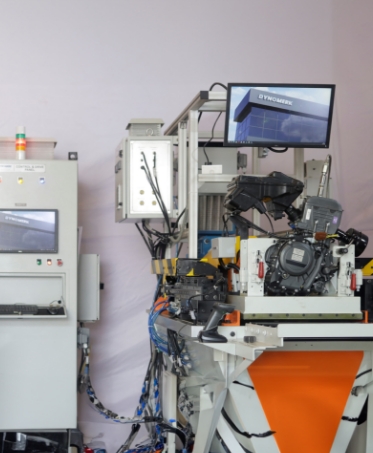

An advanced solution for comprehensive engine performance analysis. This state-of-the-art tool offers a cost-effective and flexible alternative to traditional hot firing tests. By analyzing engine waveforms without combustion, the Cold Firing Test Bench compares them with patterns of a perfect engine, enabling the identification and rejection of abnormal or faulty engines.

Designed for all fuel engines, our Cold Firing Test Bench provides accurate and reliable testing of the engine starting process, ensuring optimal performance. It simulates a wide range of starting conditions to diagnose potential issues, including fuel delivery problems, ignition system malfunctions, and critical performance parameters. Its customizable and modular design allows it to accommodate various engine types and sizes, while advanced data acquisition and analysis capabilities simplify the interpretation of critical performance data.

This fully automated test bench is built to last and requires minimal maintenance, delivering long-lasting performance and reliable results. It is an ideal solution for automotive manufacturers, engine manufacturers, and research institutions seeking to optimize engine performance and achieve maximum reliability. With exceptional accuracy, reliability, and user-friendly operation, the Cold Firing Test Bench is your dependable tool for engine performance testing.

By leveraging these advantages, the Cold Firing Test Bench enhances defect detection capabilities, reduces cycle times, and improves overall testing efficiency for engine manufacturers and research institutions.